Tension Spring Manufacturers in India

Tension Spring Manufacturers in India :

We are Tension Spring Manufacturers in India up to the following capacity :

- Wire Dia. – Up to 30 mm.

- Outer Dia. – Up to 300 mm.

- Total Length – Up to 2000 mm.

- Total Coils – As per Drawing / Data.

- Load Bearing Capacity – Up to 20 Tons. per piece

Painting and Coating used in Tension Spring manufacturing :

Following paintings / coatings are applied optionally after Tension Spring manufacturing as per user demand :

- Synthetic Enamel Paint

- Powder Coating

- Phosphate

- Zinc Coating

- etc.

Raw-material Grades used in Tension Spring manufacturing :

These Spring Steel Grades are generally used in Tension Spring manufacturing :

- BS:970 EN-42

- BS:970 EN-45

- BS:970 EN-47

- 50Cr.V4

- 50Cr.4V2

- 51Cr.V4

- 50Cr.MoV4

- 50Si7

- 55Si7

- 60Si7

- SUP-9

- SUP-9A

- SAE-5160

- IS:4454 Part-1 Grade-2

- IS:4454 Part-1 Grade-2D

- Stainless Steel

- other similar foreign grades JIS, ASTM etc.

Tension Spring manufacturing process :

1. Raw material selection :- Materials are chosen carefully to before Tension Spring manufacturing start to ensure durability, flexibility and longevity. This initial step is crucial, as the material quality will impact the Spring’s performance and ability to withstand tension.

2. Hot coiling process :- Here, the raw material is heated to high temperatures, making it malleable enough to be coiled into the desired shape while maintaining inner (ID) and outer diameters (OD) as specified. The heated material is then wound around a mandrel to form coils, allowing the Spring to achieve its fundamental structure.

3. Hook preparation :- These hooks are essential for the Spring’s function, as they enable it to attach to other components in various applications. The hooks are formed carefully to ensure they are durable and can withstand the required tension during usage.

4. Heat Treatment process :- This step is vital for enhancing the Spring’s strength and flexibility. During heat treatment, the Spring is exposed to specific temperatures, allowing it to achieve the required hardness and resilience, which ensures long-lasting performance.

5. Extension function test :- This test evaluates the Spring’s elasticity and ability to extend to the desired length without losing its form or function. Only Springs that pass this test proceed to the final stages.

6. Final dimension & quality checking :- This ensures that each Spring meets the specified tolerances for length, coil diameter and hook shape, along with confirming that it performs correctly under the designated load.

7. Painting / Coating :- This finishing step not only improves durability but also enhances the Spring’s aesthetic appeal, making it suitable for various applications.

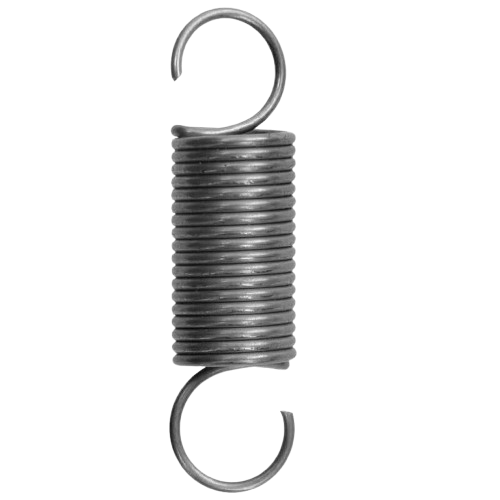

Tension Spring Hook :

Tension Spring Hook is generally available in both sides to attach between two components to operate with a pulling force. They are tightly wound (closed coil) and have hooks on both ends, which allows them to stretch and return to their original shape when tension is applied and released.

How the Tension Spring Hook looks :

The Tension Spring Hook on both sides are shaped to connect securely to components. They vary in style and can be open loops (half round), closed loops (full round) or even shaped in custom designs to ensure strong attachment. The specific shape of the hooks depends on the application requirements but all aim to provide a reliable connection and attachment.

Why Tension Spring Hook is necessary :

Attachment points :- Tension Spring Hook provide attachment points to fix the Spring between two parts, making them functional under tension.

Load distribution :- They ensure the load is evenly distributed, reducing the risk of deformation or failure.

Ease of installation :- Hooks make installation straightforward, allowing the Spring to be easily attached and removed.

Functionality in motion control :- They help maintain the position of various components and support movement and they are commonly used in applications like automotive and machinery.

How to determine Tension Spring Hook size :

Understand the Load requirements :- Before sizing the Tension Spring Hook, you need : Maximum force (load) the spring will experience (in Newtons or pounds). Spring wire diameter (affects the hook strength). Spring material (affects how much stress it can take).

Decide on Hook type :- Different hook styles handle load differently.

Common ones :-

Machine Hooks – standard, weaker under high loads.

Crossover Hooks – better for alignment and higher load.

Extended Hooks – adds flexibility for mounting.

Double Loops – for heavy loads.

How a Tension Spring Hook is formed :

A Tension Spring Hook is formed as part of the manufacturing process of Extension Springs. These Springs are designed to resist stretching and the Hook is a crucial feature that allows the spring to be attached to other components in an assembly. Here’s a step-by-step overview of how a Tension Spring Hook is formed :

Coiling the Tension Spring :- A Spring wire (typically made of steel) is coiled tightly into a helical shape using coiling machine. Tension Springs are coiled with initial tension, which holds the coils tightly together.

Forming the Tension Spring Hooks :- Once the body of the Spring is coiled, the ends of the wire are bent to create Hooks. This process can vary based on the type of hook required.

Hook bending process :- After coiling, the end of the Spring wire is gripped and bent using a hook forming tool. The machine uses dies or mandrels to accurately shape the Tension Spring hook based on the design. For stronger or more precise hooks, heat treatment may be applied after bending.

How the Tension Spring Hook works :

Connection point :- The Tension Spring hook is used to attach the spring to two different components. As these components move apart, the spring stretches and builds up tension.

Force transfer :- When stretched, the spring tries to return to its original (shorter) length. The hooks transfer this pulling force to the connected components, helping to pull them back together.

Energy storage :- As the spring stretches, it stores potential energy. The hooks must be strong enough to hold the load and not bend or break under stress.