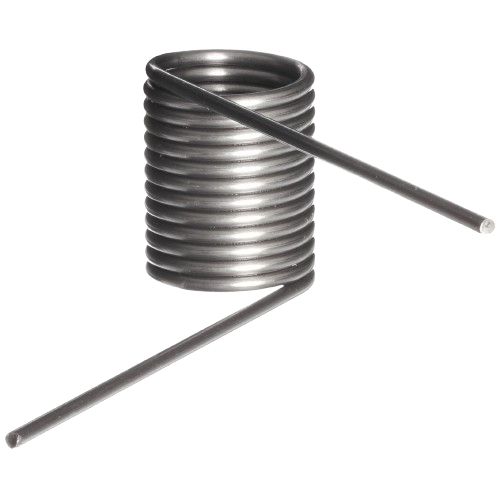

Torsion Spring Manufacturers in India

Torsion Spring Manufacturers in India :

Torsion Spring is a mechanical Spring that works by twisting its ends along its axis to store rotational or torque energy. When one end of the Spring is rotated around the center while the other end is held fixed, the Spring exerts a torque in the opposite direction proportional to the amount it is twisted. We are Torsion Spring Manufacturers in India upto the following capacity :

- Wire Dia. : Upto 30 mm.

- Out side Dia. : Upto 300 mm.

- Total Length : Upto 1000 mm.

- Total Coils : As directed.

- Load Bearing Capacity : Upto 20 Tons. (per pc.)

- Raw material : Any suitable quality Spring Steel or as directed.

Torsion Spring manufacturing process :

The Torsion Spring manufacturing process involves several stages, from raw material preparation to final finishing, to ensure strength, durability, and precision in performance. Here’s a step-by-step breakdown :

Material selection :

- Spring Steel Wire in Torsion Spring manufacturing is chosen for its strength and elasticity.

- The wire diameter and grade used in Torsion Spring manufacturing depend on the required torque, cycle life, and application.

Wire preparation :

- Cleaning & straightening : Wire is cleaned (acid wash, ultrasonic cleaning, or shot blasting) and straightened to remove bends or surface impurities in Torsion Spring manufacturing.

- Annealing (if required) : Wire may be softened for easier coiling.

Coiling / Forming :

- CNC Spring Coilers or Mechanical Coiling Machines are used to wind the wire Torsion Spring manufacturing around a mandrel to form the helical body.

- Simultaneously, legs (arms) of the torsion Spring are shaped at specific angles.

Stress relieving / Heat treatment :

- After coiling, the Spring contains internal stresses.

- Heat treatment (typically 250–500°C for carbon steel, higher for stainless) relieves stresses, improves fatigue resistance and stabilizes Spring geometry in Torsion Spring manufacturing.

Secondary operations :

- Bending/Forming of Legs : Legs are formed to required angular positions in Torsion Spring manufacturing.

- Trimming/Cutting : Excess wire is cut.

- End treatments (hook, loop, or straight) depending on design.

Grinding (if needed) :

- Ends may be ground flat for stability in some applications of Torsion Spring manufacturing.

Surface treatment / Finishing :

- Shot Peening : Bombarding with steel balls to increase fatigue strength of Torsion Spring manufacturing.

- Plating / Coating : Zinc, nickel, phosphate, epoxy, or powder coating for corrosion resistance.

- Passivation: For stainless steel to improve corrosion resistance.

Quality control & testing :

- Dimensional inspection : Coil diameter, pitch, leg angle, wire size.

- Torque testing : Ensuring required torque at specific deflection.

- Load & fatigue testing : For cycle life and consistency.

- Surface inspection : Checking for cracks, scratches, or surface defects after Torsion Spring manufacturing.

Packaging & dispatch :

- Springs are carefully packed after Torsion Spring manufacturing to avoid tangling or deformation.

- Often shipped in trays, cartons, or bulk depending on customer needs.

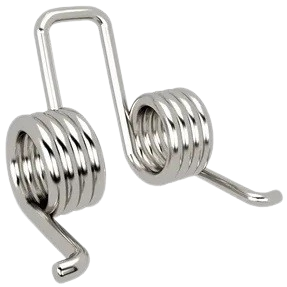

Double Torsion Springs :

A Double Torsion Spring is a type of Torsion Spring that consists of two coils wound in opposite directions and connected by a central section (or bridge). Both coils work together to provide a balanced torque, distributing the load more evenly than a single Torsion Spring.

Double Torsion Spring Function :

A Double Torsion Springs functions by storing rotational energy in its two coils when its legs (arms) are rotated, and then releasing that energy to return to its original position. Unlike a single Torsion Spring, it uses two opposing coils connected by a bridge, which makes it stronger and more balanced.

Double Torsion Spring Design :

A Double Torsion Springs is essentially two Torsion Springs connected together, usually wound in opposite directions, and joined by a central section (a bridge or spacer). This design allows the Spring to provide torque in both directions or distribute the load more evenly.

Double Torsion Spring Purpose :

Balanced torque output : The coils are wound in opposite directions, so the Double Torsion Springs resists torque evenly on both sides. This reduces side-loading and twisting of the shaft/pin it’s mounted on.

Higher torque capacity : Since there are two coils working together in, they can share the load. Provides greater torque without over stressing a single Spring.

Improved stability : The central bridge (connecting section) keeps the Spring centered and supported. Useful in precision mechanisms (switches, latches, clips).

Compact design : Can provide more torque in a smaller space compared to one large.

Durability : Load is distributed between the two coils → less stress per coil → longer fatigue life.

Double Torsion Spring Application / Uses :

Clothespins & Clips : The double coils in Double Torsion Springs provide even clamping force.

Door hinges & lids : Ovens, washing machine doors, vehicle glove boxes, toolboxes – smooth opening/closing with controlled torque.

Automotive applications : Seat recliners, trunk mechanisms, hood supports, and gear-shifting assemblies.

Medical & Dental devices : Surgical tools, clamps, or instruments needing precise return motion.

Electronics & Switches : Relays, electrical contacts, and precision switches that require stable rotational force.

Industrial equipment : Clips, clamps, or fixtures that need balanced Spring pressure.

Aerospace & Defense : Control mechanisms, latches, and components where redundancy and balance are critical.