Leaf Spring Suspension

Leaf Spring manufacturers :

We are Leaf Spring manufacturers upto the following capacity :

- Flat Thickness : Upto 20 mm.

- Flat Width : Upto 250 mm.

- Total Length : As per Drawing / required

- Total Height : As per Drawing / required

- Raw material : Any Spring Steel grades according to load requirement & functionality

What is Leaf Spring Suspension ?

Leaf Spring Suspension is a widely utilized type of suspension system found in various vehicles, particularly in trucks and larger automobiles. This system primarily consists of several layers, or ‘leaves’, of spring steel that are stacked together to form a flexible component capable of supporting the vehicle’s weight while providing a smooth ride. The configuration of these layers allows for a significant amount of flex, which is crucial in managing the forces that occur during driving, such as road bumps and turns.

The primary components of a Leaf Spring Suspension system include the leaves themselves, which are usually arched to assist in load distribution, and the shackles that connect the ends of the leaves to the vehicle’s frame. Additionally, a series of bushings, located at the connection points, facilitate movement and prevent excessive wear. These elements work in harmony to absorb shocks and maintain stability, thereby enhancing overall vehicle performance.

Historically, the Leaf Spring Suspension system has its origins in the early 20th century, where it was prominently featured in horse-drawn carriages before transitioning into automotive applications. The initial designs were rudimentary, focused primarily on basic load-bearing capacities. However, as automotive engineering evolved, so did the complexity and efficiency of Leaf Spring Suspensions. Modern iterations are often tailored for specific vehicle types, integrating advanced materials and design techniques to optimize performance. Today, Leaf Spring systems continue to be a preferred choice for many commercial and off-road vehicles due to their robustness and reliability under heavy loads.

Overall, Leaf Spring Suspension plays a vital role in ensuring a vehicle’s comfort and safety during operation, showcasing the blend of engineering innovation and practical application throughout automotive history.

Advantages of Leaf Spring Suspension :

Leaf Spring Suspension has gained popularity in the automotive industry primarily due to its numerous advantages, which cater to a wide range of vehicles including trucks, vans, and off-road vehicles. One of the foremost benefits of Leaf Spring is their cost-effectiveness. Compared to more complex suspension systems, Leaf Spring setups are generally less expensive to manufacture and install. This affordability makes them an attractive option for manufacturers looking to keep vehicle costs manageable without sacrificing quality.

Another significant advantage of Leaf Spring Suspension is its simplicity. The design of Leaf Spring consists of several layers of flexible material, usually steel, which are curved and placed one on top of the other. This straightforward design allows for easier maintenance and replacement, as there are fewer components that may require service over time. The simplicity also lends itself to more straightforward repair processes in the event of a failure, making Leaf Spring a reliable choice for fleet operators and individuals alike.

Durability is another crucial factor that enhances the appeal of Leaf Spring Suspension systems. Leaf Spring is engineered to withstand considerable stress and loads, making them particularly suitable for heavy-duty applications. Their ability to endure rough terrains and heavy weights without significant wear contributes to vehicle longevity and performance. These qualities align with the needs of commercial vehicles, which often bear substantial loads while frequently traversing rugged routes.

Lastly, the load-bearing capacity of Leaf Spring is exceptional, allowing vehicles equipped with this type of suspension to carry heavy loads with stability. This advantage is paramount for trucks and vans, which are often tasked with transporting goods. Overall, the advantages of Leaf Spring Suspension render it a favored option for various vehicles, solidifying its status in the automotive suspension landscape.

Different types of Leaf Spring :

Leaf Spring is critical components in the suspension systems of a wide range of vehicles, providing support and absorbing shocks from the road. They can be categorized mainly into two types: multi-Leaf Spring and mono-Leaf Spring. Each design exhibits unique characteristics that cater to different performance and engineering requirements.

Multi-Leaf Spring consist of several layers or leaves, which are arranged in a way that allows them to flex as they absorb impacts. This design distributes weight and load evenly, leading to improved stability and handling, particularly in heavier vehicles, such as trucks and SUVs. The increased number of leaves enhances the spring’s ability to manage heavy loads while maintaining a smooth ride. Additionally, multi-Leaf Spring can be adjusted by adding or removing leaves to suit specific vehicle applications, making them a versatile choice in suspension design.

On the other hand, mono-Leaf Spring, as the name suggests, are made from a single strip of material. This type is often found in lighter vehicles, where weight reduction is crucial. Mono-Leaf Spring generally offer advantages in terms of flexibility and simplicity, providing a smoother ride in conditions where heavy loads are not a priority. They are easier to manufacture and install, thus being a cost-effective option for many Leaf Spring manufacturers and consumers alike. However, the limited load-bearing capacity of mono-Leaf Spring can be a disadvantage when strong support is required.

In summary, the choice between multi-Leaf and mono-Leaf Spring heavily depends on the vehicle’s intended use. Multi-Leaf designs are preferable for vehicles frequently subjected to heavy loads, while mono-leaf options may be suited for lighter, more agile vehicles. Understanding these differences allows Leaf Spring manufacturers and consumers to select the appropriate Leaf Spring design to optimize performance and enhance overall vehicle dynamics.

Applications of Leaf Spring Suspension :

Leaf Spring Suspension systems have been widely utilized across various industries due to their inherent characteristics and advantages. Originally designed in the automotive sector, these systems have evolved to be applicable in numerous fields, owing to their robustness and ability to effectively absorb shocks and distribute loads.

In the realm of commercial vehicles, Leaf Spring is commonly used in trucks and buses. Their capacity to support heavy loads while maintaining a balance between strength and flexibility makes them ideal for vehicles requiring significant cargo capacity. This application ensures stability when navigating uneven terrains and enhances overall safety during transportation.

Beyond road vehicles, Leaf Spring find applications in the marine industry, especially in boats. The ability of Leaf Spring Suspension to absorb shock minimizes the impact of waves, providing a smoother ride. As a result, this system is often preferred for various types of boats, including fishing vessels and recreational crafts, where stability and comfort are paramount.

Trailers also benefit greatly from Leaf Spring Suspension. Whether for towing cargo, recreational vehicles, or horse trailers, Leaf Spring enhance the overall performance. Their simple design allows for easy maintenance, making them an economical choice for trailer Leaf Spring manufacturers and users alike. This system contributes to improved weight distribution, resulting in reduced wear and tear on both the trailer and the towing vehicle.

In the construction and heavy machinery sector, Leaf Spring is integral to the functionality of equipment such as forklifts and excavators. This suspension type not only provides increased load-bearing capacity but also mitigates the harsh impact encountered during operation. Consequently, industries that rely on heavy machinery recognize the specialized benefits of Leaf Spring systems, further cementing their value in diverse applications.

Design considerations in Leaf Spring manufacturing :

The design of Leaf Spring plays a critical role in determining their performance and suitability for various applications in the automotive and other industries. Several factors must be taken into account to ensure that the Leaf Spring manufacturing process can adequately support their intended loads while maintaining a balance in weight distribution.

One of the primary considerations in the design of Leaf Spring is their load capacity. This is essential to ensure that the spring can handle the maximum expected load without failure. Calculations involving the spring’s material properties, including tensile strength and fatigue resistance, are crucial in establishing its load-bearing capabilities. Moreover, vertical and lateral load distributions must be examined to redesign Spring that withstand different operational situations.

Furthermore, the dimensions of the Leaf Spring significantly influence its performance. The length and width directly impact stiffness and flexibility, with longer Spring generally offering more flex while shorter ones provide greater rigidity. The arc or curvature of the Spring also plays an important role; it allows for the absorption of shocks and vibrations, enhancing the overall ride quality of vehicles.

With advancements in technology, the Leaf Spring design process has been greatly enhanced by the use of computer-aided design (CAD) software. CAD enables engineers and designers to create detailed models of Leaf Spring, allowing for accurate simulations of their behavior under various loads and conditions. This innovation has led to improved precision in Leaf Spring manufacturing, enabling the production of customized Leaf Spring tailored to specific vehicle requirements. The integration of CAD into the design workflow not only improves efficiency but also enhances the performance and longevity of the final product.

Raw materials used in Leaf Spring manufacturing :

Leaf Spring manufacturing is primarily relies on various types of steel, which provide the necessary mechanical properties essential for performance and longevity. The most commonly used material in the production of Leaf Spring is high carbon steel, a choice favored for its excellent strength and resilience. High carbon steel typically contains a carbon content between 0.6% to 0.9%, allowing for a good balance between hardness and ductility. This characteristic is crucial as it enables the Leaf Spring to withstand repeated loading and deformation while maintaining their structural integrity.

Another significant material includes alloy steels that incorporate elements such as manganese, chromium, or silicon. These alloying elements enhance various properties of the steel, improving its tensile strength and fatigue resistance. Alloy steels can be particularly advantageous in applications where enhanced durability is required, as they offer improved performance in harsh environments, thus extending the life cycle of the Leaf Spring. When evaluating potential raw materials for Leaf Spring manufacturing, factors such as strength, flexibility, and durability are closely examined to ensure the chosen materials meet specific performance criteria.

Leaf Spring manufacturers often choose to use spring steel due to its unique properties tailored for spring applications. Spring steel is produced through a specific heat treatment process, enhancing its ability to recover its shape after deformation. Notably, one of the key considerations in selecting raw materials is their ability to endure cyclical loading without failing. Therefore, the careful selection of steel type influences not just the initial performance of the Leaf Spring but also their long-term functionality in various automotive and industrial applications. This ensures that the end product is reliable and meets the safety standards expected in the industry.

Design considerations in Leaf Spring manufacturing :

The design of Leaf Spring is a critical process, shaped by a variety of considerations aimed at optimizing their performance in various applications. Central to this design phase is the load capacity, which dictates how much weight a Leaf Spring can effectively support without compromising structural integrity. Each application may require different load specifications, thus demanding a comprehensive understanding of the intended use to ensure optimal performance.

Dimensions also play a significant role in the design considerations of Leaf Spring. The overall length, width, and thickness of the Spring must be meticulously calculated to achieve the desired flexibility and strength. A well-designed Leaf Spring should offer enough deflection to absorb shocks while maintaining the necessary firmness to support loads. Consequently, the interplay between these dimensions influences the overall efficacy of the Leaf Spring in its operational environment.

Curvature is another important factor in the design of Leaf Spring. The arc of the Spring affects not only the load capacity but also its ability to distribute stress evenly throughout the component. A carefully designed curvature can enhance the Spring’s performance by allowing it to react more favorably under various load conditions, supporting stability and comfort in vehicles. The development of this curvature requires a fusion of engineering principles with real-world performance expectations.

Modern design practices also increasingly rely on simulation software to refine and innovate Leaf Spring designs. This technology enables engineers to simulate real-world stresses and strains on Leaf Spring before they are physically manufactured. By analyzing various scenarios virtually, designers can anticipate potential failures and make adjustments to ensure the spring will withstand operational stresses. This integration of advanced technologies not only improves the reliability of designs but also enhances efficiency in the Leaf Spring manufacturing process, ensuring high-quality outputs that meet specific requirements.

Leaf Spring manufacturing process step by step :

The Leaf Spring manufacturing process is a meticulous method that involves several key steps to ensure the final product meets stringent quality and performance standards. The primary stages include cutting, heating, forming, and tempering, each playing a crucial role in the creation of durable and effective Leaf Spring.

The initial step in the Leaf Spring manufacturing process is cutting. Raw materials, typically high-carbon steel, are precisely cut into specified lengths. This is achieved using shearing or saw cutting techniques, which ensure that the cuts are clean and accurate. The dimensions of the cut pieces are critical, as they will determine the overall shape and performance characteristics of the finished Leaf Spring.

After cutting, the next stage is heating. The cut pieces are heated in a furnace to a specific temperature that allows for easier shaping without compromising the material’s integrity. This process, often called pre-heating, prepares the steel for subsequent forming operations. Proper heating is vital as it enhances the material’s ductility and reduces the risk of cracking when undergoing deformation.

Once heated, the forming process begins. This step involves bending the heated steel pieces into the desired shape of the Leaf Spring. Techniques such as press forming or hot forging may be employed, depending on the complexity and specifications of the design. The goal of this stage is to achieve the correct curvature and thickness while maintaining uniformity across the Leaf Spring profile.

Finally, tempering is performed after the forming process. This involves reheating the Springs to a lower temperature and then cooling them at a controlled rate. Tempering serves to relieve internal stresses in the metal, ensuring enhanced resilience and flexibility. Proper tempering significantly improves the performance characteristics of Leaf Spring, making them suitable for applications in various vehicles and machinery. By following these steps meticulously, Leaf Spring manufacturers can produce Leaf Spring that deliver reliability and strength in demanding environments.

Quality control measures in Leaf Spring manufacturing :

The Leaf Spring manufacturing involves several critical quality control measures aimed at ensuring that the final product meets industry specifications and performance standards. These measures are integral to the Leaf Spring manufacturing process and are implemented at various stages, starting from raw material selection to the final inspection of the finished product. By adhering to stringent quality control protocols, Leaf Spring manufacturers can guarantee that the Leaf Spring is not only durable but also capable of withstanding the conditions they will face in real-world applications.

One essential aspect of quality control is the inspection of raw materials. Leaf Spring manufacturers typically scrutinize the steel or composite materials used in the manufacture of Leaf Spring to ensure they conform to specified standards for tensile strength and elasticity. Advanced non-destructive testing methods, such as ultrasonic or magnetic particle inspection, may be used to detect any internal or surface defects that could compromise the integrity of the material.

During the Leaf Spring manufacturing process, various in-process inspections are conducted to monitor critical parameters such as dimensions, heat treatment, and surface finish. Automated systems may be employed for real-time monitoring, ensuring that any deviations from the predetermined specifications are promptly addressed. These checks are essential, as even minor variations can affect the performance and safety of the Leaf Spring.

Final inspections are carried out once the Leaf Spring is fully assembled. This includes testing for load capacity, fatigue resistance, and overall functionality. Leaf Spring manufacturers often employ standardized testing procedures to simulate real-life conditions under which the Leaf Spring will operate. Only those that pass rigorous testing protocols are certified for market release. By implementing comprehensive quality control measures throughout the Leaf Spring manufacturing process, manufacturers can effectively minimize defects, enhance product reliability, and ultimately provide high-quality Leaf Spring that meet consumer expectations.

Finishing processes for Leaf Spring manufacturing :

The finishing processes for Leaf Spring manufacturing is crucial in enhancing their performance, durability, and overall aesthetic appeal. These processes typically include shot peening, surface treatment, and coating, each playing a distinctive role in the Leaf Spring manufacturing process.

Shot peening is a method that involves bombarding the surface of Leaf Spring with small spherical media to induce compressive residual stress on the material. This process significantly improves fatigue resistance and extends the lifespan of Leaf Spring by preventing the initiation of cracks. The process also leads to a more uniform surface finish, which is essential for reducing stress concentrations during operation. By carefully controlling the intensity and duration of shot peening, Leaf Spring manufacturers can optimize the Leaf Spring’s mechanical properties to better withstand cyclic loading encountered in various applications.

Surface treatment is another vital finishing process that involves applying various techniques to enhance the corrosion resistance and wear performance of Leaf Spring. This may include processes like anodizing, nitriding, or phosphating. These treatments not only increase the durability of the Leaf Spring but also improve the surface hardness, making them more resistant to abrasions and environmental factors. By selecting appropriate surface treatments, Leaf Spring manufacturers can tailor the characteristics of the Leaf Spring to specific operating conditions, ensuring optimal functionality over time.

Coating is a final step that often provides both functional and aesthetic benefits to Leaf Spring. Powder coating, for instance, offers a protective layer that shields the metal from moisture, chemicals, and other corrosive elements, thereby prolonging its lifespan. Furthermore, coatings can enhance the visual appeal of Leaf Spring, which is particularly important in applications where the springs are visible. The choice of coating materials and methods is essential, as it can influence the overall look and performance of the Leaf Spring.

Through the integration of shot peening, surface treatments, and coatings, the finishing processes of Leaf Spring is designed to meet the rigorous demands of various industries, ultimately ensuring that these components deliver consistent performance and reliability.

Challenges in Leaf Spring manufacturing :

Leaf Spring manufacturing presents several challenges that can impact product quality, efficiency, and cost-effectiveness. One of the primary challenges is maintaining consistent quality throughout the production process. Variations in material properties, temperature fluctuations during treatment, and inconsistencies in the manufacturing environment can lead to discrepancies in the final product, resulting in potential failures in performance. Leaf Spring manufacturers must implement rigorous quality control measures to monitor these parameters and ensure that each Leaf Spring produced meets the required specifications.

Another significant challenge within Leaf Spring manufacturing is dealing with material defects. Leaf Spring is typically fabricated from high-strength steel, which must undergo precise processing techniques. However, material defects such as inclusions, cracks, and improper alloy composition can occur. These defects can severely impact the performance and durability of the Leaf Spring. Therefore, thorough inspection of raw materials is necessary and Leaf Spring manufacturers are increasingly employing non-destructive testing methods to identify any potential flaws before they progress through the production line.

Moreover, meeting production quotas consistently poses a challenge for many manufacturers. With fluctuating demand and the need for quick turnaround times, maintaining an efficient production schedule is crucial. To tackle this issue, Leaf Spring manufacturers are innovating by adopting advanced technologies such as automation and robotics in the Leaf Spring manufacturing processes. Automation can help expedite production while minimizing human error, thus enabling manufacturers to meet deadlines without compromising on quality.

In addition to these innovations, training skilled workforce members to operate advanced machinery effectively is essential. As the manufacturing landscape evolves, equipping employees with the necessary skills ensures that they can navigate the complexities and challenges present in the Leaf Spring manufacturing process effectively.

The role of Leaf Spring manufacturers :

Leaf Spring manufacturers play a pivotal role in the automotive and industrial sectors by providing essential components that enhance vehicle performance and stability. These manufacturers are responsible for the meticulous design, production, and delivery of Leaf Spring, which are critical to the suspension systems of various vehicles, including trucks, buses, and cars. The significance of their work cannot be overstated, as Leaf Spring is integral for improving load distribution, enhancing ride quality, and maximizing safety on the road.

The process begins with the design phase, where engineers collaborate to create Leaf Spring that meet specific performance criteria. This phase incorporates various factors such as the type of vehicle, weight loads, and operational conditions. Utilizing advanced software tools and simulation techniques, Leaf Spring manufacturers can optimize Leaf Spring designs for strength, durability, and flexibility. Precision in this stage is crucial, as any discrepancies in design can lead to reduced performance and potential safety hazards.

Once the design is finalized, Leaf Spring manufacturers proceed to the production of Leaf Spring. This stage involves the careful selection of appropriate materials, often employing high-grade steel that can withstand significant stress and strain. The Leaf Spring manufacturing process itself is typically executed through established techniques such as hot rolling, heat treatment, and surface finishing. These processes emphasize the need for reliability and consistency in product quality, as substandard Leaf Spring can compromise vehicle safety and performance.

Moreover, Leaf Spring manufacturers must ensure timely delivery and adherence to industry standards and regulations. This commitment to quality and precision fosters trust with clients across various industries, including transportation, construction, and agriculture. Thus, the role of Leaf Spring manufacturers is vital, not only in producing high-quality components but also in supporting the broader goals of efficiency and safety in the sectors they serve. As the demand for innovative suspension solutions continues to grow, these manufacturers will play an increasingly critical role in advancing technologies and refining the products they supply.

Types of Leaf Spring :

Leaf Spring is essential components in automotive suspension systems, designed to absorb shock and provide support, stability, and load-carrying capabilities. Leaf Spring come in various types, each with unique characteristics and applications. The most common types include multi-Leaf Spring, mono-Leaf Spring, Parabolic Leaf Spring and Elliptical Leaf Spring.

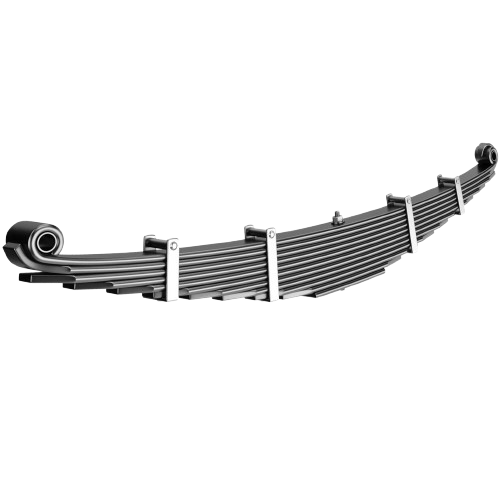

Multi-Leaf Spring is comprised of several individual leaves stacked together, creating a robust and flexible structure. This design allows for better load distribution and enhanced stability under heavy loads, making them a popular choice in trucks and larger vehicles. However, multi-Leaf Spring tend to be heavier and may produce a less comfortable ride due to their stiffness. Additionally, as they wear over time, they may suffer from friction between the leaves, which can lead to reduced performance.

In contrast, mono-Leaf Spring consist of a single, continuous leaf. This simplicity in design results in a lighter framework, contributing to improved vehicle handling and ride quality. Mono-Leaf Spring is typically used in smaller cars and vehicles where agility is prioritized over load-bearing capacity. One downside is their limited load-carrying capacity compared to their multi-leaf counterparts, making them less suitable for heavy-duty applications.

Lastly, Parabolic Leaf Spring feature an asymmetrical design where the width of the Leaf Spring varies. This unique construction allows for a significant reduction in weight while providing excellent ride comfort and flexibility. Parabolic Spring also optimize the distribution of forces without the drawbacks of inter-leaf friction often found in multi-leaf systems. Due to their advanced design, parabolic Spring is commonly used in modern vehicles requiring superior suspension performance, but they may have higher production costs.

In summary, understanding the different types of Leaf Spring is essential for selecting the appropriate suspension system to meet specific vehicle requirements. Each type has its own merits and drawbacks, making them better suited for various applications, from commercial trucks to passenger cars.

Mono-Leaf Spring simplicity and performance :

Mono-Leaf Spring is a type of suspension component characterized by a single curved plate, designed to provide a smooth ride while minimizing weight. Their simplicity in design not only distinguishes them from traditional multi-Leaf Spring but also offers several advantages in terms of performance and maintenance. One of the primary benefits of mono-Leaf Spring is weight savings. By utilizing a single leaf, these Spring can significantly reduce the overall weight of a vehicle, which can directly contribute to improved fuel efficiency and enhanced performance, particularly in lightweight sports cars and compact vehicles.

Moreover, the streamlined structure of mono-Leaf Spring allows for a more uniform distribution of stress and load across the spring during compression and rebound. This characteristic results in better handling and stability as the vehicle faces various road conditions. Drivers often appreciate the responsive nature of vehicles equipped with mono-Leaf Spring, as they tend to deliver a progressive response when traversing bumps, improving the overall driving experience.

Mono-Leaf Spring have become increasingly suitable for modern automotive applications, particularly in vehicles designed for performance-oriented driving and efficiency. As automotive Leaf Spring manufacturers seek to enhance fuel economy and reduce emissions, the lightweight nature of mono-Leaf Spring makes them an appealing choice. Furthermore, their inherent simplicity can lead to lower production costs and reduced maintenance requirements, which are beneficial for both manufacturers and consumers.

In summary, mono-Leaf Spring exemplify a balance of simplicity and performance, making them an interesting option for modern vehicle designs. Their lightweight, efficient structure not only improves driving dynamics but also aligns with contemporary automotive goals focused on efficiency and sustainability.

Multi-Leaf Spring design and functionality :

Multi-Leaf Spring is a prominent type of suspension system used primarily in heavy-duty vehicles such as trucks and trailers. Their design consists of multiple layers, or “leaves,” typically made from high-strength steel. Each leaf is incrementally shorter than the one below it, allowing for better load distribution and flexibility. The layered construction helps to absorb shocks and maintain vehicle stability under significant loads, making them particularly suitable for commercial applications.

One of the principal advantages of multi-Leaf Spring is their ability to evenly distribute weight across the suspension system. This characteristic not only enhances ride comfort but also strengthens the vehicle’s overall structure. As the load increases, the additional leaves engage progressively, which prevents the suspension from bottoming out. This feature is crucial in heavy-duty contexts where vehicles frequently transport large payloads over uneven terrain.

Moreover, the design of multi-Leaf Spring allows for a certain degree of adjust ability. By altering the number of leaves or their configuration, Leaf Spring manufacturers can tailor the suspension system to achieve desired levels of stiffness and responsiveness. This adaptability is particularly beneficial for vehicles that may encounter a range of weight conditions. However, despite their many advantages, multi-Leaf Spring come with certain drawbacks. One noteworthy concern is the weight of the Spring themselves. The additional layers can contribute to an overall increase in vehicle weight, which may impact fuel efficiency and handling.

Furthermore, while the rigidity that multi-Leaf Spring provide is beneficial for load-carrying capacity, it can lead to a stiffer ride compared to other suspension systems, such as Leaf Spring with fewer layers or air suspension. Consequently, finding the right balance in the design is essential to meet the requirements of specific applications. In conclusion, multi-Leaf Spring is a vital component in the suspension systems of heavy-duty vehicles, providing significant load-bearing capabilities while also presenting some potential challenges related to weight and ride comfort.

What is Parabolic Leaf Spring ?

Parabolic Leaf Spring represent a sophisticated evolution in the design of vehicle suspension systems, distinguished by their unique, tapered shape. Unlike traditional multi-Leaf Spring, which consist of multiple layers of flat steel plates, parabolic Spring is crafted with a singular, parabolic arc. This innovative form provides a more efficient distribution of load and improves overall functionality.

The core components of Parabolic Leaf Spring include the main Leaf Spring, which is typically constructed from high-strength steel, and the spring eye attachments that connect the spring to the vehicle chassis. The parabolic structure allows for a reduction in weight while enhancing load-bearing capabilities, contributing to better vehicle dynamics. Each parabolic leaf in the setup is designed to flex independently, thereby facilitating a smoother ride and improved vehicle control.

One of the significant advantages of Parabolic Leaf Spring is their capacity to adjust to varying load conditions, thanks to their flexible design. The parabolic shape helps enhance the spring’s response under dynamic conditions, offering superior performance when compared to traditional Leaf Spring. This responsiveness is essential for vehicles that experience diverse operating environments, such as off-road or heavy-duty applications.

As the industry moves toward improving vehicle handling and comfort, the adoption of Parabolic Leaf Spring is on the rise. Their efficient design not only contributes to a reduction in weight but also plays a vital role in minimizing the un sprung mass of the vehicle, further enhancing ride quality. The combination of these factors makes Parabolic Leaf Spring a popular choice in modern suspension systems, reflecting their importance in the automotive engineering landscape.

The design of Parabolic Leaf Spring :

Parabolic Leaf Spring is engineered to optimize their performance while minimizing weight, offering superior flexibility and load capacity. The design philosophy behind these Spring is rooted in the parabolic geometry that allows them to distribute loads more evenly along their length. Unlike traditional multi-Leaf Spring, which consist of several individual leaves stacked together, parabolic Spring taper from a wide end to a narrow end, creating a more efficient load-bearing structure. This design inherently reduces the number of leaves required, resulting in a lighter component without compromising strength.

The Parabolic Leaf Spring manufacturing process is typically begins with high-quality raw materials such as alloy steel, which is chosen for its exceptional elasticity and durability. The steel is subjected to hot forging techniques that shape it into the desired parabolic form. This process not only enhances the strength of the material but also allows for precise control during the shaping stage. Once the basic form is achieved, the spring is then subjected to processes such as heat treatment and surface finishing, which further improve its tensile strength and fatigue resistance.

Another critical feature of Parabolic Leaf Spring is their ability to flex more efficiently, providing better shock absorption and ride comfort, particularly in automotive applications. This flexibility is pivotal in applications ranging from commercial vehicles to off-road machinery. The design also minimizes friction between leaves, as the parabolic design reduces the number of contact points, thereby prolonging the lifespan of the spring. Overall, the thoughtful design of Parabolic Leaf Spring allows for enhanced performance characteristics that are highly beneficial across various industries.

How parabolic Leaf Spring function :

Parabolic Leaf Spring is a crucial component in the suspension systems of various vehicles, engineered to provide a balance between load-bearing capacity and ride comfort. Their design contrasts significantly with traditional multi-Leaf Spring, primarily due to their unique shape and curvature, which significantly influences their performance. The parabolic profile allows for a progressive rate of deflection, meaning that the Leaf Spring can absorb and dissipate energy more effectively when encountering bumps or uneven surfaces.

The mechanics underlying Parabolic Leaf Spring begin with the distribution of load along the curved structure. Unlike conventional Leaf Spring, where the load is concentrated over multiple leaves, a Parabolic Leaf Spring gradually transitions from a wider base to a narrower tip. This design leads to a more even distribution of stress, resulting in reduced weight while maintaining strength. As the Leaf Spring deflects under load, the curvature aids in distributing the forces more evenly, which minimizes stress concentrations that could lead to failure.

The curvature of the Parabolic Leaf plays a pivotal role in enhancing ride quality. When a vehicle encounters a bump, the spring’s curvature allows it to flex more efficiently, absorbing shocks and reducing the impact felt by passengers. This improved shock absorption is particularly beneficial in off-road and heavy-duty applications, where the terrain may be unpredictable. Additionally, the lighter weight inherent to the parabolic design contributes to improved fuel efficiency and responsiveness of the suspension system.

Overall, the interplay between the curvature and load distribution in Parabolic Leaf Spring ensures optimal function and durability, making them increasingly popular in modern vehicle design. Their capacity to provide a smooth ride while carrying significant loads underscores their efficacy and importance in automotive engineering.

Advantages of Parabolic Leaf Spring over traditional Spring :

Parabolic Leaf Spring offer several distinct advantages when compared to traditional multi-Leaf Spring, enhancing both performance and durability. One of the primary benefits is the enhanced ride quality that Parabolic Leaf Spring provide. Their unique design consisting of a single, tapered leaf enables a smoother ride by reducing road vibrations. This attribute is particularly advantageous in off-road vehicles or heavy-duty applications where comfort is paramount. By distributing the load more evenly, parabolic Spring absorb shocks more effectively than their traditional counterparts.

Another significant advantage is improved handling, particularly in vehicles subjected to heavy loads. The lightweight nature of Parabolic Leaf Spring contributes to a lower center of gravity, which helps maintain stability during maneuvering. As a result, vehicles equipped with Parabolic Leaf Spring exhibit improved response times and precision steering, crucial for both safety and performance in challenging driving conditions.

In terms of durability, Parabolic Leaf Spring demonstrate greater resistance to wear and fatigue. Traditional Spring comprise multiple layers that can bind together under strain, potentially leading to premature failure. Conversely, the single-leaf design of parabolic Spring minimizes friction between layers, subsequently prolonging their lifespan. This durability translates into lower maintenance costs over time, making them an economically advantageous choice for fleet operators and commercial vehicles.

A further highlight of Parabolic Leaf Spring is their capacity for better load distribution. This attribute not only enhances the handling capabilities but also prevents localized stress points that can lead to structural failures. Real-world applications, such as in the transport industry, have shown that vehicles fitted with Parabolic Leaf Spring often achieve higher payload efficiencies. Consequently, their benefits of enhanced ride quality, improved handling, increased durability, and better load distribution position Parabolic Leaf Spring as a superior alternative to traditional spring systems.

Applications of Parabolic Leaf Spring in various industries :

Parabolic Leaf Spring is renowned for their unique design and performance characteristics, making them a popular choice across several industries. Automotive Leaf Spring manufacturers often incorporate Parabolic Leaf Spring into vehicle suspension systems due to their ability to provide superior ride quality and handling. Unlike traditional multi-Leaf Spring designs, Parabolic Leaf Spring offer a significantly reduced weight, which leads to improved fuel efficiency. This is especially beneficial in passenger vehicles, where comfort and efficiency are paramount.

In the heavy-duty vehicle sector, Parabolic Leaf Spring is favored for their durability and reliability. Trucks and buses equipped with these Spring exhibit enhanced load-carrying capacity while maintaining a softer ride, which minimizes the stress on chassis components. The reduced friction between leaves results in less maintenance, which is critical for fleet operators who aim to reduce operational costs over time.

Trailers, especially those designed for transporting heavy loads, also benefit greatly from Parabolic Leaf Spring. The unique characteristics of this spring design allow for better articulation, resulting in improved stability while traversing uneven terrain. This ensures that the load remains balanced, reducing the risk of sway and improving overall safety during transport.

Interestingly, the aerospace industry has started to explore the advantages of Parabolic Leaf Spring in some specialized applications. Their lightweight nature and ability to handle high loads make them suitable for use in certain aircraft designs, contributing to weight savings and improved performance. The adaptability of Parabolic Leaf Spring demonstrates their versatility, proving that their applications extend well beyond conventional uses in road vehicles.

Overall, the widespread adoption of Parabolic Leaf Spring in these diverse industries underscores their significance in modern engineering. Their unique design characteristics provide distinct advantages that enhance performance, safety, and efficiency across a range of applications.

How to install Parabolic Leaf Spring (A step-by-step guide) :

Installing Parabolic Leaf Spring requires careful attention to detail, as these components are crucial for vehicle suspension systems. To begin the installation process, ensure you have the right tools on hand: a jack, jack stands, wrenches, sockets, and potentially a spring compressor. It is also advisable to have a torque wrench for tightening bolts to manufacturer specifications, as this ensures safety and performance.

Before starting, park your vehicle on a flat surface and engage the parking brake. Once you are prepared, lift the rear or front of the vehicle with a jack and support it securely with jack stands. Remove the wheels to gain access to the suspension system. Carefully unbolt the existing Leaf Spring, paying attention to the location of each part, as this will inform how to install the new Parabolic Leaf Spring correctly.

Next, position the new Parabolic Leaf Spring in alignment with the mounting points. It’s essential to ensure the spring’s curvature faces the right direction for optimal performance. Once properly aligned, fasten the Spring using the original bolts or the new ones provided with the Parabolic Leaf Spring. Be mindful of the spring eye bushing installations—these need proper lubrication to function effectively.

After securing the Spring, recheck all connections for tightness, using your torque wrench to apply the correct settings as outlined in your vehicle’s service manual. Following this, you can replace the wheels and lower your vehicle back to the ground with the jack. Once on the ground, ensure the suspension system operates smoothly by checking the overall ride height and conducting a final inspection.

In summary, take your time during each step of the installation process. Adhering to safety protocols and understanding the components will help avoid common pitfalls, resulting in a successful installation of Parabolic Leaf Spring.

What is an Elliptical Leaf Spring ?

Elliptical Leaf Spring is characterized by their distinct shape, which resembles an elongated ellipse. This unique design offers significant advantages over traditional rectangular Leaf Spring. The geometry allows for more even distribution of weight across the spring, improving load-bearing capacity and enhancing ride comfort. Unlike the conventional Leaf Spring, where layers are stacked, the Elliptical design consists of a single piece that is typically wider in the center and tapers towards the ends. This shape helps reduce stress concentrations that can lead to failures, making Elliptical Leaf Spring a more durable choice for various applications.

The structure of an Elliptical Leaf Spring includes several components: the main leaf, secondary leaves, and additional support elements, although in many designs, the emphasis is primarily on the main leaf due to its prominence in handling loads. The curvature of the spring is engineered to provide optimal flexibility while maintaining structural integrity. This configuration not only supports the vehicle’s weight but also allows for vertical movement, effectively absorbing shocks from irregular surfaces, which enhances the overall performance during operation.

Common materials used in the manufacture of Elliptical Leaf Spring include high-carbon steel and composite materials. High-carbon steel is favored for its strength and resilience, while composite materials lend themselves well to applications requiring a lightweight solution without sacrificing durability. The choice of materials directly influences performance characteristics, such as fatigue resistance and the ability to withstand harsh environmental conditions. Consequently, engineers must carefully consider the materials employed in the design of Elliptical Leaf Spring to ensure optimal functionality and longevity in their intended applications.

How Elliptical Leaf Spring function :

Elliptical Leaf Spring is sophisticated components that play an essential role in the suspension systems of vehicles. Their unique geometry and design allow them to absorb shock and distribute loads effectively. The mechanics behind how these Spring function are rooted in the principles of elasticity and force. When a vehicle encounters uneven terrain, the Elliptical Leaf Spring bends and flexes, absorbing the impact and minimizing the transmission of vibrations to the cabin.

The primary function of an Elliptical Leaf Spring is to support the weight of the vehicle while maintaining its stability and comfort. This is achieved through the spring’s inherent elasticity, which allows it to deform under load and return to its original shape when the load is removed. As the Leaf Spring compresses, it generates a restoring force that counteracts the weight of the vehicle, enabling a smooth ride. The design of Elliptical Leaf Spring increases their effective length, which enhances their load-bearing capacity compared to traditional Leaf Spring.

When load is applied, the Elliptical shape allows for an even distribution of stress across the spring, reducing the chance of localized failures. The bending action of the spring results in a significant deflection that mitigates harsh jolts to the vehicle and its passengers. Moreover, the specific curvature and length of the Elliptical Leaf Spring aid in improving the overall ride quality, especially in heavy-duty applications such as trucks and trailers.

In summary, Elliptical Leaf Spring function through a balanced interplay of elasticity, bending, and load distribution. Their design not only enhances vehicle ride quality but also contributes to the safety and durability of both the suspension system and the vehicle as a whole.

Design specifications of Elliptical Leaf Spring :

Elliptical Leaf Spring is engineered for optimal performance in various applications, particularly in automotive and heavy machinery sectors. The design specifications of these Spring is critical as they directly influence both functionality and durability. Key aspects such as dimensions, material considerations, and load-bearing capacities are essential when assessing the performance of Elliptical Leaf Spring.

The geometry of Elliptical Leaf Spring is characterized by their elongated, oval-like shape, which plays a vital role in distributing loads evenly. The primary dimensions include overall length, width, and thickness, which must be carefully tailored to the specific application. A common advantage of Elliptical Leaf Spring is their ability to deliver greater load-bearing capacity while maintaining a compact size compared to traditional Leaf Spring. This is achieved through their unique curvature, which allows for a more efficient energy absorption mechanism when subjected to force.

Material selection is another crucial factor impacting the specifications of Elliptical Leaf Spring. Typically, spring steel is favored due to its excellent mechanical properties, including high tensile strength and fatigue resistance. Additionally, the surface treatment of the materials, such as shot peening or coating, can enhance the lifespan and performance of the Spring, minimizing wear and susceptibility to environmental factors.

Load-bearing capacities are determined by a combination of the spring’s geometry and the material used. Each spring must be meticulously designed to handle the specific demands placed upon it, such as the weight of the vehicle or equipment it supports, as well as dynamic loads that may arise during operation. Furthermore, proper calculation of deflection and stress distribution is critical to ensure safety and reliability. Ultimately, understanding these design specifications enables engineers and technicians to make informed decisions when choosing and implementing Elliptical Leaf Spring in various applications.

Materials used in Elliptical Leaf Spring :

Elliptical Leaf Spring is critical components in various suspension systems, and the selection of materials significantly impacts their performance. Traditionally, high-carbon steel has been the material of choice for Leaf Spring manufacturers due to its exceptional strength and durability. High-carbon steel provides the necessary rigidity and can endure substantial loads while maintaining its integrity. Its flexibility is vital for the spring’s functionality, allowing it to absorb shocks and return to its original shape. However, prolonged use under heavy loads can lead to material fatigue, warranting the exploration of alternatives.

In recent years, composite materials have gained popularity for their distinct advantages over conventional steel. Composites, typically composed of resin reinforced by fibers, offer incredible fatigue resistance and are significantly lighter than traditional steel. This reduction in weight not only enhances the performance of the vehicle by improving fuel efficiency but also facilitates easier handling during installation. Additionally, composites can be engineered to have specific flexural properties, tailoring the spring characteristics to meet different performance needs.

Furthermore, the corrosion resistance of composite materials presents a vital advantage in environments where exposure to moisture and corrosive elements is prevalent. Unlike high-carbon steel, which may require protective coatings to prevent rust, composite materials naturally resist degradation over time, ensuring a longer service life. However, the initial production costs of composite Elliptical Leaf Spring can be higher than steel, making them a consideration for specialized applications where performance and durability are paramount.

In summary, while traditional high-carbon steel provides the essential qualities required for Elliptical Leaf Spring, newer composite materials offer remarkable benefits in terms of weight, fatigue resistance, and longevity. The choice of material ultimately depends on the specific application, performance requirements, and cost considerations.

Advantages of Elliptical Leaf Spring :

Elliptical Leaf Spring have gained popularity in various applications due to their numerous advantages over traditional spring designs. One of the primary benefits is their efficient weight distribution. The unique shape of Elliptical Leaf Spring allows for a more even distribution of load across the spring components, which helps to mitigate stress concentrations. This characteristic is especially valuable in automotive and heavy-duty vehicle applications, where maintaining a balanced load can enhance vehicle stability and safety.

Another significant advantage lies in the improved ride quality offered by Elliptical Leaf Spring. The design allows for greater deflection without compromising structural integrity, which results in a smoother ride over uneven surfaces. This is particularly beneficial in off-road vehicles and trucks that frequently navigate rough terrains, as it helps to absorb shocks and vibrations effectively. Consequently, drivers and passengers experience reduced fatigue and improved comfort during transit.

In terms of practicality, Elliptical Leaf Spring is also lighter than their conventional counterparts. This reduction in weight not only contributes to improved fuel efficiency in vehicles but also enhances the overall payload capacity. The lighter design enables Leaf Spring manufacturers to optimize vehicle weight, thereby increasing performance without compromising safety. Additionally, the enhanced load-carrying capacity of Elliptical Leaf Spring makes them ideal for heavy-load applications, such as in commercial transport and industrial machinery.

The benefits of Elliptical Leaf Spring extend beyond automotive use; they are also employed in various industrial applications where shock absorption and load stabilization are crucial. The unique shape facilitates a smoother transfer of forces, making them a preferred choice in equipment subjected to dynamic loading conditions. Overall, the adoption of Elliptical Leaf Spring can result in significant performance enhancements across multiple sectors, highlighting their versatility and operational advantages.

Applications of Elliptical Leaf Spring :

Elliptical Leaf Spring have gained widespread application across various industries, thanks to their unique design and functionality. One of the most prominent sectors that utilize these Spring is the transportation industry, particularly in commercial vehicles. Trucks and vans often incorporate Elliptical Leaf Spring to ensure a smooth ride and enhance load-carrying capacity. Their inherent ability to distribute weight evenly allows for improved stability, which is essential when navigating uneven terrains or while transporting heavy cargo.

In addition to commercial vehicles, Elliptical Leaf Spring is extensively employed in railway systems. The design of these Spring helps in maintaining track alignment and provides the necessary flexibility to accommodate the dynamic loads experienced during train operations. This characteristic is crucial in enhancing the safety of rail travel while minimizing wear and tear on tracks and rolling stock. The spring’s shape allows for efficient energy absorption, contributing to a more comfortable ride for passengers and minimizing forces transmitted to the track structure.

Moreover, the automotive performance sector also benefits from Elliptical Leaf Spring. Some high-performance sports cars use these Spring due to their ability to provide optimal ride quality and handling characteristics. The design’s unique geometry enables better dampening of shocks, thus enhancing road grip and overall vehicle control. This adaptability makes Elliptical Leaf Spring favorable for modifications in vehicles aiming for improved performance or specific handling attributes.

Overall, the versatility of Elliptical Leaf Spring, characterized by their design and functionality, makes them indispensable in various applications, from heavy commercial vehicles and resilient railway systems to the sophisticated engineering of performance cars. The ability of these Spring to address specific operational demands underscores their vital role in advancing vehicle design and functionality across multiple domains.

Installation and maintenance of Elliptical Leaf Spring :

When installing Elliptical Leaf Spring, careful attention to detail is imperative to ensure that the suspension system functions effectively. The installation process typically begins with safely lifting the vehicle and placing it on jack stands. Before removing the old Spring, it is crucial to inspect all associated components, including the spring hangers, shackles, and bolts, to identify any that may require replacement as well. After removing the old Spring, examine the mounting surfaces for any corrosion or damage, and clean them to ensure a proper fit for the new Elliptical Leaf Spring.

Next, position the new Leaf Spring onto the vehicle’s frame, aligning it with the spring hangers. It may be beneficial to enlist the help of a second person during this process, as Elliptical Leaf Spring can be cumbersome. Once aligned, attach the mounting hardware, ensuring that bolts are tightened to the manufacturer’s specified torque settings. After installation, it is recommended to double-check all connections and conduct a thorough visual inspection to confirm proper alignment and secure fastening.

Regular maintenance of Elliptical Leaf Spring is essential for maintaining their performance and extending their lifespan. A proactive approach should include routine inspections every few thousand miles, checking for signs of wear, cracks, or deformation. Examine the Leaf Spring packs for rust or corrosion, particularly in regions that experience harsh weather conditions. If any issues are detected, it is advisable to address them promptly to prevent further deterioration.

Additionally, lubricating the bushings helps reduce friction, ensuring smoother operation. This maintenance should be carried out in accordance with the Leaf Spring manufacturer’s guidelines. By following these installation and maintenance practices, vehicle owners can ensure that their Elliptical Leaf Spring remain reliable and continue to deliver optimal performance over time.

What are semi Elliptical Leaf Spring ?

Semi Elliptical Leaf Spring is a type of suspension system commonly found in vehicles, known for their unique arc-like structure that resembles half of an ellipse. This distinctive design allows the Leaf Spring to effectively distribute weight and absorb shocks, providing stability and support for the vehicle, especially when carrying heavy loads. Unlike full Elliptical or other types of Leaf Spring, semi Elliptical variations are characterized by their tapered ends, which help improve flexibility and performance by providing a graduated response to load changes.

The construction of semi Elliptical Leaf Spring typically involves high-carbon steel, due to its advantageous properties such as strength, durability, and resistance to deformation. The materials used are often subjected to heat treatment processes that enhance their mechanical properties, leading to increased lifespan and reliability. This Leaf Spring manufacturing methods include forging, which shapes the steel into its desired form, and the layering of multiple sheets of steel, allowing for variable stiffness and support characteristics. The Spring can also be treated with protective coatings to prevent corrosion and extend their service life.

When featuring semi Elliptical Leaf Spring, it is essential to recognize that their design not only contributes to vehicle performance but also affects handling and ride comfort. The unique geometry of these Spring allows them to handle both vertical loads and lateral forces, making them suitable for various applications, from trucks and buses to trailers and recreational vehicles. Compared to other types of spring systems, such as coil Spring or full Elliptical Leaf Spring, semi Elliptical Leaf Spring provide an effective balance between load-bearing capacity and flexibility, ensuring a safer and more controlled driving experience.

How semi Elliptical Leaf Spring works :

Semi Elliptical Leaf Spring is a pivotal component of a vehicle’s suspension system, designed to absorb shocks and control vehicle dynamics. Their unique design consists of several layers of flexible steel called leaves, which are bound together at one end and connected to the vehicle’s frame at the other. This configuration allows the spring to flex under load, effectively distributing forces exerted on it during operation.

When a vehicle encounters an uneven surface, the weight causes the leaves to compress, enabling the spring to absorb shock as the load is distributed evenly. This is further enhanced by the arc shape of the spring; as the leaves flex, they help maintain stability and ensure that the vehicle remains grounded to the road. The geometry of semi Elliptical Leaf Spring facilitates effective load-bearing capabilities, allowing them to support significant weight while providing a smooth ride.

The performance of these Spring is critical in varying driving scenarios. For instance, during a hard turn or rapid acceleration, the semi Elliptical Leaf Spring help to maintain optimal wheel alignment, reducing body roll and enhancing vehicle control. This responsiveness not only contributes to the ride comfort of passengers but also to the overall safety of the vehicle.

Additionally, the absence of complex moving parts in the semi Elliptical design reduces maintenance requirements, making them a popular choice for commercial vehicles and heavy-duty applications. The Spring’ ability to function effectively under compression while providing the necessary resilience means that they play a critical role in both passenger comfort and vehicle longevity. Overall, the mechanics of semi Elliptical Leaf Spring exemplify the balance between structural integrity, load distribution, and driving comfort.

Advantages of Semi Elliptical Leaf Spring :

Semi Elliptical Leaf Spring offer several advantages that make them a popular choice in both commercial and recreational vehicles. One significant benefit is their remarkable durability. Constructed from high-quality steel, these Spring is designed to endure harsh conditions, withstand heavy loads, and resist wear over time. This durability translates into a longer lifespan for vehicles, reducing the need for frequent replacements and minimizing downtime.”

Cost-effectiveness is another important advantage. While the initial investment in semi Elliptical Leaf Spring may be higher than other spring types, their extended lifespan and low maintenance requirements can lead to substantial savings over time. Their design also allows for straight forward installation, which reduces labor costs for Leaf Spring manufacturers and workshop operations alike.

Moreover, semi Elliptical Leaf Spring provide excellent performance in load-carrying situations. Their unique shape and multi-leaf construction enable them to distribute tension evenly across the structure, which results in enhanced stability and better handling characteristics. For instance, vehicles commonly used in the transport sector—such as trucks and trailers—benefit from the robust support these Spring offer during heavy loads, ensuring a smooth ride even over uneven terrains.

Real-world examples highlight the effectiveness of semi Elliptical Leaf Spring in various applications. For example, many pickup trucks, which often need to carry significant payloads, use these Leaf Spring in their suspension systems. Additionally, utility vehicles and certain designs of buses often employ semi Elliptical Leaf Spring to enhance the overall performance and reliability under weighty conditions. The reduction in body sway and improved load distribution significantly contribute to the comfort and safety of passengers and cargo alike.

Common applications of Semi Elliptical Leaf Spring :

Semi Elliptical Leaf Spring is an essential component in various industries and vehicle types, particularly those that require enhanced stability and load-bearing capabilities. These Spring is most commonly employed in commercial vehicles, such as delivery trucks and freight carriers, where the need for durable suspension systems is paramount. Due to their inherent design, which allows for significant flexibility and strength, semi Elliptical Leaf Spring can efficiently manage substantial loads while maintaining ride comfort and safety.

In the realm of heavy-duty trucking, Semi Elliptical Leaf Spring play a critical role in supporting the weight of large payloads. They are adept at absorbing shock and reducing the effects of road irregularities, thus ensuring a smoother ride. Their load-carrying capacity makes them particularly suitable for vehicles such as flatbeds and tractor-trailer combinations. Furthermore, the durability of these Spring is a noteworthy aspect, as they are engineered to withstand the rigors of constant use in challenging environments.

Trailers, which often accompany heavy-duty trucks, also benefit significantly from the incorporation of Semi Elliptical Leaf Spring. These Spring provide robust support, enhancing stability and load distribution, which is crucial when carrying bulky or unevenly distributed cargo. Off-road vehicles, including trucks used in construction and agricultural applications, utilize Semi Elliptical Leaf Spring to improve traction and control on rough terrains. The flexibility of these Spring allows the vehicle’s suspension to adapt to bumpy surfaces, thereby enhancing performance and safety.

In summary, the widespread use of Semi Elliptical Leaf Spring in various vehicles, including commercial trucks, trailers, and off-road vehicles, underscores their significance in utility applications. Their capacity to bear heavy loads while ensuring ride comfort and stability makes them an invaluable element in modern engineering solutions across multiple industries.

Parabolic Leaf Spring vs Elliptical Leaf Spring :

When comparing Parabolic Leaf Spring vs Elliptical Leaf Spring, it is important to examine their structural design and the implications of these designs on performance. Parabolic Leaf Spring feature a single, gradually tapering leaf design, which provides an efficient weight distribution and enables effective load management. This design allows for a reduced number of leaves compared to traditional multi-Leaf Spring, resulting in a lighter overall weight. In contrast, Elliptical Leaf Spring adopt an elongated, oval shape, which facilitates a unique loading configuration. This shape distributes loads evenly across the spring and reduces stress concentrations, although it typically involves a more complex setup.

Regarding load capacity, Parabolic Leaf Spring tend to excel in applications requiring significant weight reduction without compromising performance. The design enhances the vehicle’s handling and ride quality, making it suitable for modern light-duty trucks and SUVs. Elliptical Leaf Spring, having a broader arc, may be more suitable for heavy-duty applications where maintaining a stable load during dynamic conditions is crucial. The inherent design allows for greater axle movement, which is vital for off-road vehicles that encounter various terrains.

Another critical factor to consider is stress distribution. Parabolic Spring excel at minimizing stress due to their tapered design, which allows for more predictable flexing and reduces the risk of premature failure. Conversely, Elliptical Leaf Spring’ configuration permits significant deflection, thereby absorbing more shocks and vibrations. However, this may be accompanied by increased stress at specific points during operation, necessitating careful design considerations.

Ultimately, the choice between parabolic and Elliptical Leaf Spring depends on the specific requirements of the vehicle and its intended use, striking a balance between load capacity, performance, and durability.

Performance testing : Parabolic Leaf Spring vs Elliptical Leaf Spring

Performance testing of Parabolic Leaf Spring and Elliptical Leaf Spring is vital in understanding their respective benefits and drawbacks in different applications. The methodology involves rigorous evaluations under controlled conditions that simulate real-world scenarios. The primary focus during the testing phase includes load-carrying capacity, ride comfort, and durability under stress, with each factor being crucial for determining the suitability of a spring type for specific vehicular contexts.

Initially, load-carrying ability is assessed by subjecting each spring type to progressively increasing weights. Parabolic Leaf Spring, known for their progressive stiffness, generally exhibit superior load management compared to their Elliptical counterparts. The parabolic design allows for the distribution of stress more uniformly across the spring, reducing the risk of failure under heavy loads. Test results consistently indicate that Parabolic Leaf Spring outperform Elliptical Spring in maximum load handled, often allowing for a higher payload without compromising safety.

When evaluating ride comfort, the focus shifts to how each spring type absorbs shocks and vibrations during transit. In tests conducted on various surfaces, Parabolic Leaf Spring often provide a more comfortable ride due to their ability to flex more efficiently, enhancing damping characteristics. On the contrary, Elliptical Leaf Spring, despite their traditional design, tend to transmit more vibrations to the vehicle chassis, leading to a less refined ride experience.

Durability testing involves placing each spring type under simulated long-term stress conditions. Parabolic Spring typically demonstrate greater resistance to fatigue due to their design, which minimizes stress concentrations. Conversely, Elliptical Spring, while robust in construction, tend to fail under prolonged heavy use, highlighting the material limitations of their design. Overall, performance testing reveals that while both spring types serve important functions, parabolic Spring often lead in load capacity, ride comfort, and longevity, making them a favored option in modern vehicles.

Which Leaf Spring is right for you ?

Choosing the appropriate Leaf Spring for your vehicle entails a careful evaluation of various factors, including performance requirements, load capacity, comfort, and driving conditions. Both Parabolic Leaf Spring and Elliptical Leaf Spring offer distinct advantages that cater to different needs. Understanding these features is vital for making an informed decision that aligns with your unique preferences.

Parabolic Leaf Spring is designed for enhanced flexibility and weight distribution, making them suitable for applications where load variability is a consideration. They typically deliver a smoother ride due to their ability to absorb shocks more effectively. This characteristic makes them a favorable choice for off-road vehicles and those frequently encountering challenging terrain. Furthermore, their lightweight construction contributes to improved fuel efficiency, which is an attractive aspect for many Leaf Spring manufacturers and vehicle owners alike.

In contrast, Elliptical Leaf Spring excel in applications requiring high strength and load-bearing capabilities. Their design allows for a more robust suspension system that can handle heavier loads without compromising performance. For vehicles that frequently tow or carry significant weight, Elliptical Spring may offer the superior durability and dependability necessary for such applications. Additionally, their ability to provide consistent handling under various conditions is a considerable advantage for commercial vehicles.

Ultimately, the decision between parabolic and Elliptical Leaf Spring should be based on your specific driving habits, vehicle usage, and desired performance characteristics. Take into account factors such as weight distribution, expected ride comfort, and maintenance requirements. By carefully weighing these considerations, you can choose the Leaf Spring that best suits your needs, ensuring optimal performance and longevity for your vehicle’s suspension system.