Leaf Spring Suspension

Leaf Spring suspension is a type of Spring made from a single or a few tapered, parabolic-shaped steel strips, used in vehicles to support weight and absorb shocks. Unlike traditional multi-Leaf Springs, which use multiple layers of flat steel, a Leaf Spring suspension gradually tapers in thickness and width from the center to the ends, creating a curved, parabolic shape. This design allows for smoother ride quality, reduced friction between layers and better overall performance with fewer leaves. It is commonly used in heavy-duty vehicles like trucks and off-road vehicles.

Leaf Spring suspension manufacturers :

● We are Leaf Spring suspension manufacturers up to the following capacity :-

Flat Thickness – Upto 20 mm.

Flat Width – Upto 250 mm.

Total Length – As per Drawing or Specification.

Total Height – As per Drawing or Specification.

● Raw material grades used in Leaf Spring suspension :-

BS:970 EN-45 / BS:970 EN-47 / 50Cr.V4 / 50Cr.4V2 / 51Cr.V4 / 50Cr.MoV4 / 50Si7 / 55Si7 / 60Si7 / SUP-9 / SUP-9A / SAE-5160 etc. and others similar Foreign Grades JIS, ASTM etc.

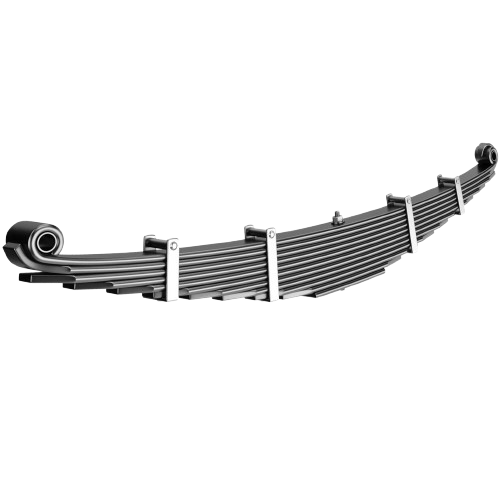

Parabolic Leaf Spring :

Parabolic Leaf Spring consists of one or more tapered leaves whose thickness varies parabolically from the center (thickest point) to the ends (thinnest point). Unlike conventional multi-leaf springs that have many leaves with constant thickness stacked together, parabolic springs use fewer leaves (often 1 to 3), reducing weight and friction.

● Parabolic Leaf Spring Pros and Cons :

Pros :

Better Ride Comfort – It reduced inter-leaf friction gives a smoother, more comfortable ride.

Lighter Weight – Fewer leaves and tapered design reduce the overall weight of the suspension system.

Improved Flexibility – The parabolic shape allows the spring to flex more freely and respond better to road conditions.

Reduced Maintenance – Less wear and tear due to fewer parts and less friction between leaves.

Noise Reduction – Minimal metal-to-metal contact means quieter operation.

Progressive Spring Rate – Offers a soft ride under light loads and stiffens under heavier loads.

Cons :

Higher Manufacturing Cost – Requires precise tapering, making them more expensive to produce than conventional leaf springs.

Lower Load Capacity – Not as strong as multi-leaf springs for extremely heavy-duty applications.

More Vulnerable to Overloading – Can deform or fail if consistently overloaded, due to fewer leaves.

Reduced Lateral Stability – With fewer leaves, they may offer less resistance to side forces without additional stabilizers.

Elliptical Leaf Spring :

Elliptical Leaf Spring is an early type of mechanical suspension system used in vehicles, especially in carriages and early automobiles. Its design is based on an elliptical shape, formed by two semi-elliptical leaf springs connected end-to-end.

● Parabolic Leaf Spring vs Elliptical Leaf Spring :

| Feature | Parabolic Leaf Spring | Elliptical Leaf Spring |

|---|---|---|

| Shape & Design | Semi-elliptical shape with parabolic-tapered leaf/leaves | Full elliptical shape formed by two opposing semi-elliptical springs |

| Leaf Profile | Tapered (thick at center, thin at ends) | Constant thickness in most designs |

| Number of Leaves | Typically 1 to 3 | Two full stacks (top and bottom), many leaves |

| Weight | Lightweight | Heavy and bulky |

| Ride Comfort | Superior comfort due to reduced inter-leaf friction | Moderate comfort for older designs; less effective than modern systems |

| Maintenance | Low maintenance (fewer parts, less friction) | Higher maintenance (more parts, greater wear potential) |

| Load Handling | Good, with progressive response under varying loads | Adequate for early vehicle loads; not suited for modern demands |

| Modern Usage | Common in light trucks, buses, SUVs | Rare, mostly in vintage cars and carriage restorations |

| Cost | Higher initial manufacturing cost due to precision tapering | Cheaper to produce historically, but not used in modern manufacturing |

| Durability | Durable under proper load conditions | Prone to fatigue and sagging over time under heavy loads |