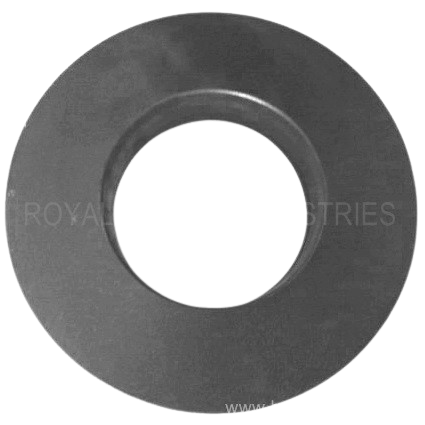

Disc Spring

Disc Spring manufacturers :

We are Disc Spring manufacturers up to the following capacity :

- Thickness – Up to 20 mm.

- Outer diameters – Up to 400 mm.

- Inner diameters – As per Drawing / Data.

- Height – As per Drawing / Data.

Raw-materials grades :

- BS:970 EN42

- BS:970 EN45

- BS:970 EN47

- 50Cr.V4

- 50Cr.4V2

- 51Cr.V4

- 50Cr.MoV4

- 50Si7

- 55Si7

- 60Si7

- SUP9

- SUP9A

- SAE 5160

- others similar Foreign Grades JIS, ASTM etc.

Manufacturing process :

Raw-material selection : The quality of the Disc Spring is significantly influenced by the choice of raw materials. Typically, high tensile steel or alloy steels are selected due to their excellent mechanical properties, which are essential for the performance of the Spring under load.

Shaping : Disc Spring manufacturing involves the initial shaping of the Spring. This is accomplished through either forging or stamping methods, where a high degree of precision is crucial. Forging tends to enhance the strength of the material through grain refinement, while stamping offers cost-effectiveness for large production volumes.

Heat treatment : After shaping, Disc Spring manufacturing process enters the heat treatment stage, where defined temperatures are utilized to alter the material’s properties, enhancing durability and flexibility.

Quality checking : Disc Spring manufacturing process undergoes a series of rigorous inspections and quality checks. These procedures are imperative to ensure that each Disc Spring meets industry standards and specifications.

Surface finishing and Coating : Final stage of Disc Spring manufacturing process is done by surface finishing processes, which include grinding or coating to improve resistance against corrosion.

Packing : Finally, the Disc Spring are packaged for distribution, maintaining their integrity for end users.

Choosing right manufacturers :

Technical expertise : A Disc Spring manufacturers that possesses a deep understanding of materials and engineering principles will be better equipped to design and produce high-quality Disc Spring.

Experience : Disc Spring manufacturers with a longer history and a proven track record may offer reliability and a wealth of knowledge. It is beneficial to investigate their reputation by seeking feedback from previous clients.

Customization capabilities : Vital when selecting a Disc Spring manufacturers. Every application may have unique specifications and a manufacturer that offers customization is likely to cater to varying needs. During the evaluation process, it is advisable to inquire about the range of customization options they provide and the processes they utilize for such modifications.

Production capacity : It is vital before choosing a Disc Spring manufacturers, as it directly impacts lead times and the ability to fulfill large or urgent orders. Engaging in a dialogue regarding their production capabilities and turnaround times can shed light on whether a Disc Spring manufacturers can adequately support your business requirements.

Customer service : A Disc Spring manufacturers who values communication and offers robust support throughout the production and delivery processes can significantly enhance the partnership experience. Evaluating their responsiveness to inquiries and their willingness to collaborate will ensure that your needs are addressed effectively.

What is Disc Spring DIN 2093 ?

Disc Spring DIN 2093 is a comprehensive standard that governs the design and manufacturing of Disc Spring, which are a vital component in various mechanical systems. Established by the Deutsches Institut Für Normung (DIN), this standard provides essential guidelines for producing high-quality Disc Spring.

One of the primary aspects of Disc Spring DIN 2093 pertains to the standardized dimensions of Disc Spring. These specifications detail the geometrical parameters such as inner diameter, outer diameter and thickness that all manufacturers must adhere to.

Disc Spring DIN 2093 issues guidelines concerning material specifications. The standard typically recommends specific materials that can be utilized in the fabrication of Disc Spring; these include high-carbon steel and other alloys known for their resilience and fatigue resistance.

Disc Spring DIN 2093 delineates testing protocols to verify the performance and reliability of manufactured Disc Spring. These testing methods assess critical parameters such as load capacities, deflection characteristics and fatigue life. By adhering to these prescribed tests, manufacturers can guarantee that their products meet the rigorous demands of their intended applications, thereby enhancing safety and efficiency in machinery performance.

It’s types :

Disc Spring DIN 2093 include circular, oval and rectangular configurations, with circular Spring being the most prevalent. These shapes are critical in ensuring efficient load-bearing capabilities while managing compression and deflection properties.

Convex shape, which is designed to provide high elasticity and load capacity

Conical Disc Springs are notable for their tapered shape that promotes a uniform load distribution, making them suitable for applications requiring precise movement

Flat Disc Spring are advantageous for applications that necessitate minimal vertical space while ensuring adequate tension.

It’s characteristics :

Load capacity : Disc Spring DIN 2093 load capacity is influenced by the Spring’s material, thickness and diameter. Typically made from high-quality materials such as carbon steel or stainless steel, these Disc Spring offer exceptional strength and resilience. The load capacity is defined by the Disc Spring DIN 2093 ability to withstand significant compressive forces without permanent deformation, making them ideal for applications that involve cyclic loads.

Dimension : This is is equally important for Disc Spring DIN 2093 as they determine how well the Spring fits into a specific assembly. The specification provides parameters such as outer and inner diameters, thickness and free height, ensuring consistency across various applications.

It’s application :

Automobile : The automotive industry is one of the leading sectors employing Disc Spring DIN 2093, primarily in suspension systems. These Springs facilitate load distribution and help maintain vehicle stability during operation. Their compact design and effective Spring characteristics ensure that vehicles can handle road irregularities without compromising comfort or safety.

Aerospace : Disc Spring DIN 2093 is employed in various applications, including landing gear assemblies and actuator mechanisms. Their ability to withstand extreme forces while adding minimal weight contributes significantly to the overall efficiency and safety of aircraft. Furthermore, their low maintenance requirements and durability make them ideal for high-performance aerospace systems.

Industrial Machinery : Another prominent application of Disc Spring DIN 2093 can be found here particularly in clamping and locking devices. These Spring plays a crucial role in ensuring mechanical components remain securely fastened during operation, preventing potential failures and enhancing the longevity of the equipment.

What is Disc Spring Washer ?

Disc Spring Washer, also known as Belleville Washer, is a type that characterized by their unique conical shape, which offers excellent flexibility and the ability to withstand high loads without deformation. This particular design allows them to function effectively in various critical applications, including automotive, aerospace and industrial machinery.

Manufactured from an assortment of materials, Disc Spring Washer can be crafted from steel, stainless steel or other alloys, each offering distinct advantages. Steel Disc Spring Washer is favored for their durability and ability to handle heavy loads, while stainless steel variants are preferred in environments prone to corrosion due to their resistance to rust and degradation.

The versatile nature of Disc Spring Washer makes them suitable for applications that require constant force, such as securing components in place, compensating for wear, and preventing loosening due to vibration. This effectiveness is largely attributed to the washer’s capacity to maintain a continuous load under compression, thus ensuring that mechanical assemblies remain stable and reliable over time.

How it’s works :

Disc Spring Washer play a crucial role in maintaining tension and load retention in various mechanical assemblies. Their design allows them to effectively manage significant axial loads through a unique principle of compression. Unlike conventional Washer, Disc Spring Washer is inherently designed to deform elastically under load, which results in the extraordinary ability to store energy.

When subjected to axial load, a Disc Spring Washer experiences compression, resulting in a change in shape that allows it to absorb energy. The amount of force that the washer can handle is dependent on various factors, including the material composition, thickness, and diameter of the washer itself. Each of these critical aspects influences its load capacity and deflection characteristics.

The performance of Disc Spring Washer also relies on the principle of variable deflection. As the load is applied, the deflection of the washer increases, allowing for a higher performance regarding clamping force retention. Additionally, factors such as temperature fluctuations and environmental conditions can affect their operational reliability.

It’s types :

Disc Spring Washer are essential components in many industrial applications, providing excellent load-bearing capabilities and versatility. They come in various designs, primarily categorized into single and multi-spiral configurations. Understanding these types can aid in selecting the appropriate Disc Spring washer for specific tasks.

Single Disc Spring Washer : They typically consist of a single circular disc that can deform under load. This deformation allows them to accommodate variations in load and provide a constant clamping force. Single Disc Spring are often utilized in applications where space is limited, as they require less installation depth. Their rigidity and reliability make them suitable for use in machinery where vibration is a concern, such as automotive and aerospace industries.

Multi-spiral Disc Spring Washer : This is consists of two or more interlaced discs, which allows for increased load capacity in a compact form factor. These types are particularly advantageous in applications that require a higher amount of axial load or deflection. Their stacked design allows the distribution of load over a larger area, making them ideal for heavy machinery and high-performance equipment.

It’s application :

Disc Spring Washer, also known as Belleville Washer, is an essential component found across a multitude of industries due to their unique mechanical properties. Their ability to provide consistent performance under varying loads makes them particularly valuable in applications requiring reliable clamping and load distribution.

Automotive industry : Disc Spring Washer is frequently utilized to maintain tension in assemblies such as suspension components and exhaust systems. Their design allows them to accommodate dynamic loads while minimizing the risk of fatigue.

Aerospace : Here, the weight-to-strength ratio is critical, and Disc Spring Washer are commonly used in securing aircraft components where relaxation of the fasteners could lead to catastrophic failures. Additionally, their ability to absorb shock loads without permanent deformation is essential in aircraft design.

Machinery sector : Disc Spring Washer is often integrated into mechanical assemblies to manage load variations. Their use in clutch mechanisms, for example, helps to ensure smooth operation by compensating for wear and maintaining the necessary tension.

Construction industry : Utilized Disc Spring Washer to improve the durability of structures and machinery. For instance, they are utilized in bolted connections within bridge construction and heavy machinery, helping to prevent loosening over time due to dynamic forces.

It’s advantages :

Disc Spring Washer, often referred to as Belleville Washer, offer a range of advantages that make them a preferred choice in various applications. One of the primary benefits of employing Disc Spring Washer is their remarkable space-saving properties. Unlike other types of Washer, which may require increased thickness to achieve desired performance, Disc Spring Washer maintain an efficient profile.

Another significant advantage of Disc Spring Washer is their reliability when subjected to dynamic loads. They exhibit superior elasticity and allow for effective load distribution, which ensures consistent tension even under fluctuating and varying loads. This feature is particularly crucial in applications where machinery experiences vibrations or shocks, as the Disc Spring washer can adjust to such changes without losing its effectiveness.

Longevity is another key benefit associated with Disc Spring Washer. Their design allows for the dissipation of energy when subjected to stress, which minimizes wear and tear over time. Many industrial applications require components that can withstand harsh operating conditions and Disc Spring Washer is constructed to provide superior operational longevity compared to traditional Washer.

It’s installation and maintenance :

The Disc Spring washer should be positioned in a manner that allows it to achieve its maximum deflection capacity; the convex side typically faces the bolt head or nut in most applications. This positioning ensures that the axial load is distributed evenly across the surface, allowing the washer to perform its function of absorbing shock and maintaining tension.

Preloading the Disc Spring Washer correctly is also critical. Preload refers to the initial load applied to the washer, which is key to its operation. To achieve the recommended preload, the fasteners securing the assembly should be tightened to the specified torque values established by the manufacturer’s guidelines.

It is important to avoid over-torquing, which can lead to deformation of the Disc Spring Washer, thus diminishing its load-bearing capabilities. A torque wrench can be an essential tool in this process, ensuring that the washer retains its designed characteristics under operational stress.

Maintenance of Disc Spring Washer should not be overlooked, as regular inspections can extend their service life and prevent potential system failures. It is advisable to check for signs of wear, such as cracking or deformation, which may signal that the washer is nearing its end of life.